| Sign In | Join Free | My portofva.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My portofva.com |

|

Brand Name : XIANRUN BLOWER

Model Number : ZR-BC SERIES

Certification : CE, ISO 9001

Place of Origin : XINXIANG

MOQ : 1

Price : 50-50000

Payment Terms : L/C, D/A, D/P, T/T

Supply Ability : 10000

Delivery Time : 5-45DAYS

Packaging Details : WOODEN PACKING

Voltage : 220V/380V/440V/480V/660V

Blade material : Stainless Steel,Cast Iron,Steel plate,Q345 (16Mn) manganese steel

Air volume : 800 - 90000m3 / h

Power : 5 - 350KW

Warranty : 1 Year

Color : Customer's Requirement

Material : Steel,316L,Carbon Steel /Stainless Steel,Q235

Type : Centrifugal Fan,Multi-wings Industrial Centrifugal Exhaust Blower Fan,centrifugal blower,high pressure blower

Applications : Cooling systems

Name : Industrial Axial Flow Fan

Use of high temperature centrifugal fan:

1, used in drying industry, boiler industry, cleaning industry, painting industry, food drying industry.

2, the use of temperature between 100℃-180℃.

3, the conveying gas is air or other gas that is not spontaneous combustion, not self-explosion, no winding, harmless to the human body, and no corrosion to steel materials. It can also be used as a non-corrosive, non-spontaneous combustion, non-viscous material hot gas, steam, smoke transport. Other similar performance can also be selected, but the temperature of the conveying medium must not exceed its rated temperature range.

4. No viscous substances are allowed in the gas, and the dust and hard particles contained are not more than 150mg/m3. If the dust content is large, no less than 85% dust removal device must be installed before the fan to reduce the dust content of the flume into the fan to improve the life of the fan.

High temperature fan structure:

1. The high temperature fan is mainly composed of impeller, casing, air inlet, motor, connector, cooling blade and other parts.

2, the impeller adopts multi-wing single inlet centrifugal impeller, made of high quality galvanized sheet or cold rolled steel plate, and the blade is designed according to the aerodynamic principle. The impeller consists of 10 backsloping airfow-type blades, curved-type front disks, and flat rear disks. The material is made of high strength, good durability and high quality steel plate, and is strictly corrected for dynamic and static balance. Good air performance, high efficiency, smooth operation.

3. The air inlet adopts the form of convergent streamline vortex reduction, the air flow loss is small, and the working efficiency of the high temperature fan is high.

4. The high temperature fan shell and motor are installed and connected with metal castings, the motor shaft head is installed with cooling blades, and the outer wall of the metal casting is opened with inlet and outlet pipe interfaces to cool the metal casting and shaft head to ensure the normal operation of the motor under high temperature.

5. The motor adopts special high temperature motor, the fluid part of the high temperature fan adopts temperature resistant material, and the cooling structure has reliable performance. Compared with other boiler induced draft fans, simple structure, convenient maintenance, high cost performance advantages.

High temperature fan installation:

1. There are two forms of this high temperature fan. From the side of the motor, the impeller clockwise rotation is called the right-hand fan, represented by "right"; The impeller inverse needle rotation is called the left cyclone, denoted by "left".

2. The outlet position of the high temperature fan is expressed by the outlet Angle of the casing. The fan №1.5 ~ 6 is made into an adjustable type when it leaves the factory, and the use unit is installed into the required position according to the requirements. The adjustment range of air outlet position is 0° -255 °, and the interval is 45°. The transmission mode is "A" type direct transmission.

Key Features

Material: Cast Iron, Carbon Steel, Stainless Steel.

Efficiency: 80%-90%

Applications

Please advise us the USAGE and following Parameter.Our engineering Dept will recommend the most suitable product for you.

| Air volume/air flow | m3/h | |

| Total pressure or static pressure | Pa | |

| Medium temperature | °c | |

| Voltage | V | |

| Frequency | Hz | |

| Altitude of operation place | m |

|

|

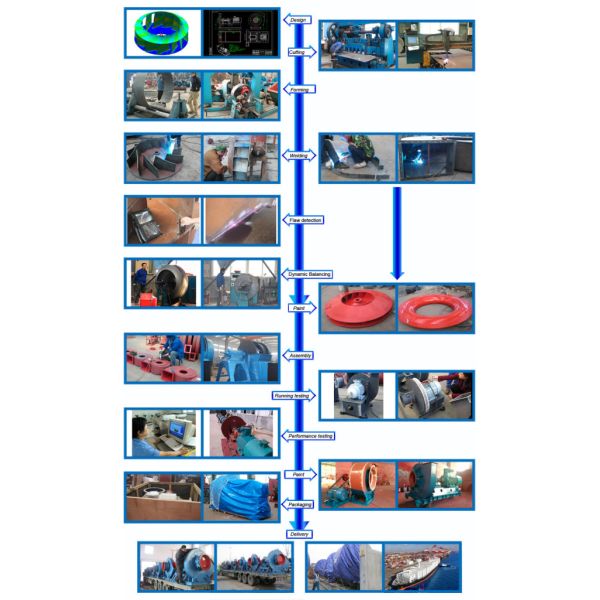

560rpm - 2900rpm High Temperature Centrifugal Fan For Boiler Industry Images |